American manufacturing has been a troubled sector in recent decades. Between 2000-2010, the manufacturing sector lost close to 6 million jobs and closed 64,000 plants. Between 2010 and 2020, the productivity of U.S. manufacturers declined both in absolute terms and compared to key foreign competitors. The massive U.S. trade deficit in goods rose in 2018 to $891 billion, including more than $120 billion in advanced technology goods.

How will U.S. manufacturing compete with lower-wage, lower-cost competitors? Advanced manufacturing, with its potential gains in efficiency and productivity, offers a solution. Although the U.S. formed 16 advanced manufacturing institutes to help bring on new manufacturing technologies, a purely technology-focused approach will not be enough. The institutes are working to develop technologies in areas such as digital production, robotics, additive manufacturing, flexible electronics, photonics, sensor and systems, and biofabrication. However, our workforce education system is not ready to provide the training we need in these new technologies.

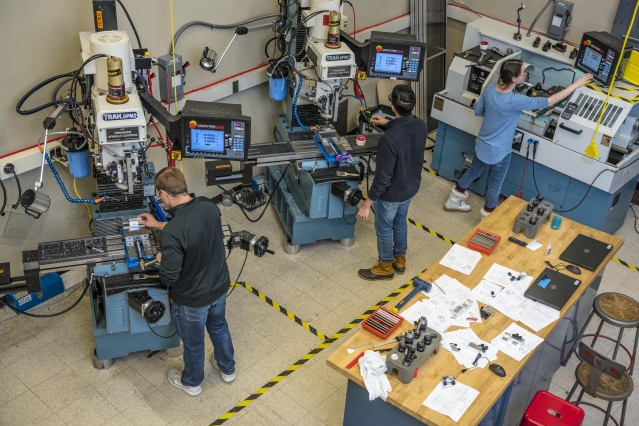

Concerned about the strength of the U.S. industrial base, the Department of Defense funded the MassBridge project. MassBridge will plan and develop advanced manufacturing programs for community colleges and vocational-technical high schools in Massachusetts. The DoD hopes that MassBridge, once successful, can also be a model for efforts in other states.

It is important to understand, up front, that the success of a new workforce training program for advanced manufacturing skills will only succeed if the state’s manufacturing firms are adopting new advanced manufacturing technologies. Firms, particularly SMEs, are reluctant to train skills for new equipment they don’t yet have. Therefore, workforce training efforts must proceed in parallel with advanced technology implementation efforts, including Massachusetts’ unique M2I2 program to assist firms and research institutions in acquiring advanced manufacturing capital equipment.

Overall, development and dissemination of advanced manufacturing content requires use of existing curricula where available for closer-in manufacturing technologies and new curricula for further-out technologies. For both, the manufacturing innovation institutes may be able to play a constructive role in support of the MassBridge project. DoD ManTech’s pending online platform to collect and disseminate advanced manufacturing online content could be a useful resource. The MassBridge advanced manufacturing education content could be implemented through the improved delivery systems discussed above, with employer or educational-led collaborations helping to develop and broadcast the new content, and adopting a series of new best practices to do so.